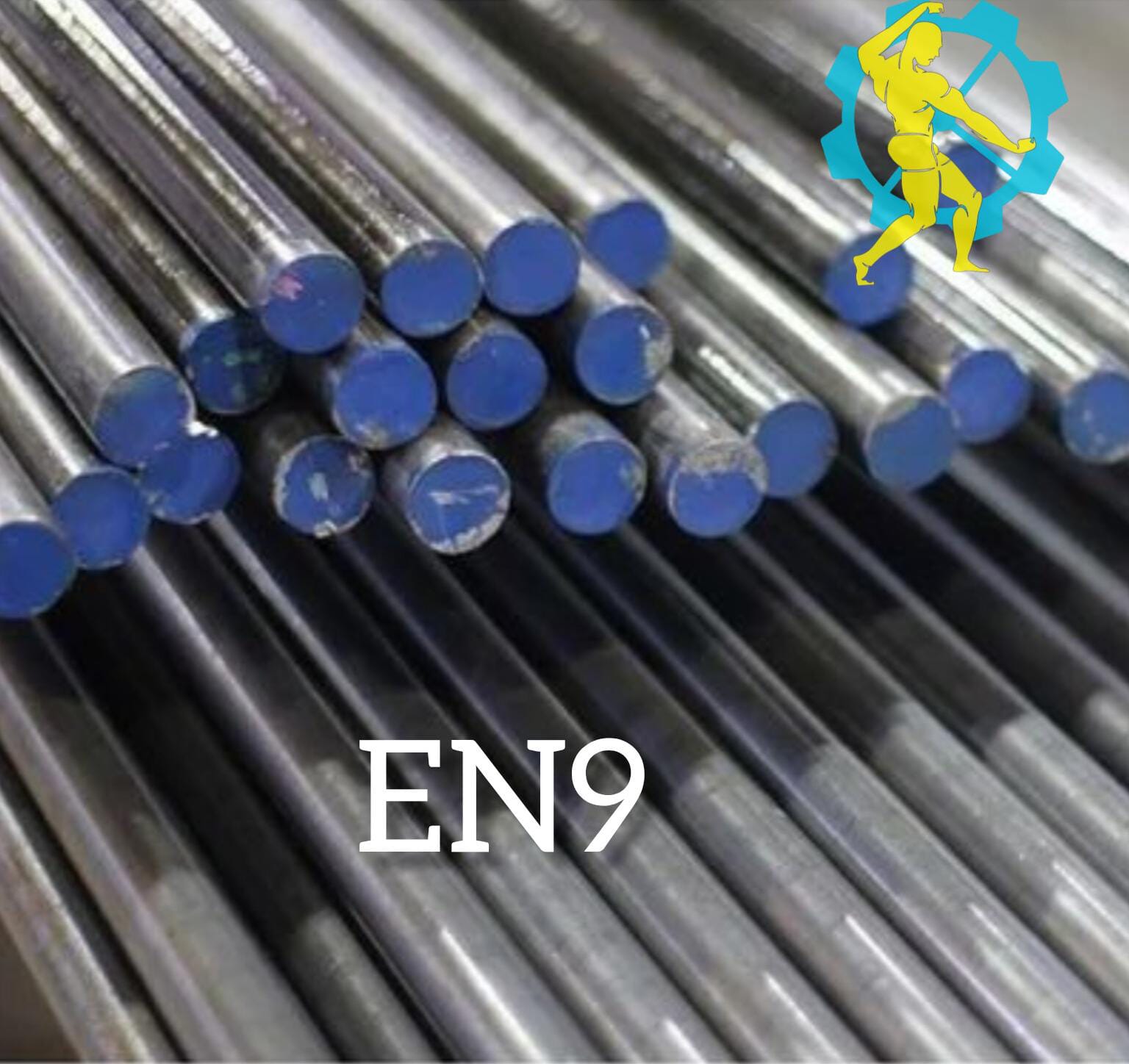

EN9 steel, classified as a medium carbon steel grade, contains approximately 0.45% carbon. Renowned for its exceptional wear resistance properties, EN9 steel rods can undergo flame or induction hardening to achieve a remarkable surface hardness, further enhancing their wear resistance capabilities. The provided text specifies the criteria for carbon and carbon-manganese, alloy, free-cutting, and stainless steels that are typically supplied in a brightly finished condition after being cold-processed. Carbon Steel EN9 is widely utilized in various engineering fields for a multitude of applications. It is commonly employed in the manufacturing of shafts, axes, knives, bushes, crankshafts, screws, woodworking drills, hammers, and sickles. Stock Availability of Carbon Steel EN9: Carbon Steel EN9 materials are normally available in forms like EN9 Rough Round. We supply En9 materials as per our Customer’s Cutting Requirement. Applications of Carbon Steel EN9: Carbon Steel EN9 is used commonly for many general engineering applications. Typical applications include, shafts, axes, knives, bushes, crankshafts, screws, sickles, wood working drills and hammers.

Send Message